“Bricks are the building blocks of history, connecting the past to the present and shaping the foundations of a sustainable future.”

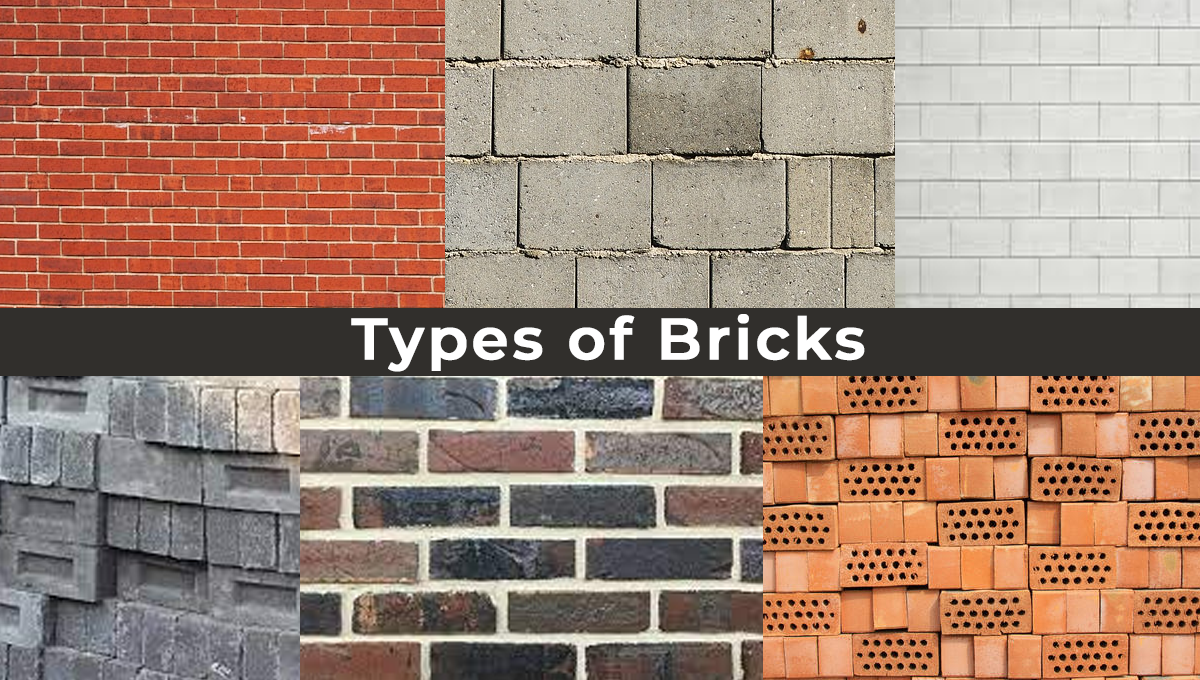

Bricks have been a fundamental building material for centuries, shaping the architecture of civilizations throughout history. From ancient civilizations like the Egyptians to modern urban landscapes, bricks have proven their durability, versatility, and aesthetic appeal. With advancements in technology and construction techniques, the types of bricks available today offer a wide range of options for various applications in the construction industry. In this article, we will explore different types of bricks and their applications in construction.

Burnt Clay Bricks (Red Bricks)

Burnt clay bricks are one of the most common and traditional types of bricks used in construction. These bricks are manufactured by moulding clay and then firing them in a kiln at high temperatures. Burnt clay bricks are known for their strength, durability, and thermal insulation properties. They are primarily used in residential and commercial construction for load-bearing walls, facades, and partitions. The porous nature of these bricks also helps regulate indoor temperature and humidity, making them an eco-friendly choice.

Shop for quality Red Bricks here!

Concrete Bricks

Concrete bricks are made by mixing cement, sand, aggregate, and water, which are then poured into moulds and cured. These bricks offer enhanced strength and can be produced in various colours and textures. Concrete bricks are widely used in both structural and decorative applications. They are used for building walls, pavements, pathways, and even in landscaping projects. The ability to control the mixed composition makes them adaptable to different strengths and design requirements.

Fly Ash Bricks

Fly ash bricks are an eco-friendly choice for traditional clay bricks. They are made using a mix of fly ash – a byproduct of coal combustion – cement, sand, and water. These bricks are lightweight, have a lower water absorption rate, and possess good thermal insulation properties. Fly ash bricks find applications in various construction projects, including residential, commercial, and industrial structures. Their production also helps in reducing environmental impact by utilizing waste material.

Engineering Bricks

Engineering bricks are specially designed for their durability and strength. They are often used in areas exposed to severe weather conditions, heavy loads, and chemical exposure. These bricks are manufactured at higher temperatures and have low water absorption rates. They are commonly used in the construction of foundations, basements, retaining walls, and in areas where high resistance to frost and abrasion is required.

Sand-lime Bricks

Sand-lime bricks are made by mixing sand, lime, and water under high pressure. These bricks are then cured through a process of steam curing. Sand-lime bricks offer high compressive strength, low water absorption, and excellent acoustic insulation properties. They are commonly used in load-bearing walls, facades, and interior partition walls. Additionally, their smooth texture and uniform size make them suitable for architectural purposes.

Clinker Bricks

Clinker bricks are produced by over-burning regular clay bricks, giving them a distinct appearance characterized by irregular shapes, textures, and earthy colours. Due to their unique aesthetic appeal, clinker bricks are often used in architectural designs to add visual interest to facades, fireplaces, and accent walls. While they are not as widely used as other brick types, their unique appearance makes them stand out in contemporary construction.

Perforated Bricks

Perforated bricks, also known as hollow bricks, have holes or perforations that run through the bricks’ length. These bricks are lighter in weight, which makes them easier to handle during construction. They are often used for non-load-bearing walls, partitions, and infill areas. The holes in perforated bricks also provide improved thermal insulation and soundproofing capabilities.

Insulating Bricks

Insulating bricks are designed with a focus on thermal insulation properties. They are used in areas where temperature regulation is crucial, such as in kilns, furnaces, and industrial chimneys. These bricks have low thermal conductivity and are made from materials like clay, shale, or silica, combined with insulating aggregates. Their ability to withstand high temperatures while minimizing heat transfer makes them indispensable in high-temperature environments.

Conclusion

Bricks remain an integral part of the construction industry due to their durability, versatility, and aesthetic appeal. The various types of bricks available today cater to different construction needs, ranging from load-bearing structures to decorative facades. As technology continues to evolve, so does the production and application of bricks, allowing architects, engineers, and builders to create innovative and sustainable structures. Whether it’s the time-tested burnt clay bricks or the environmentally friendly fly ash bricks, each type plays a unique role in shaping the built environment of today and tomorrow.